Every business owner knows the roof is more than just a cover. It protects employees, inventory, and equipment from weather while also playing a major role in energy efficiency and long-term costs. That`s why choosing the right commercial flat roofing solution is such a critical decision. Whether you`re constructing a new facility or maintaining an existing building, understanding your options gives you the power to make smart investments.

Why Commercial Buildings Need Flat Roofs

Walk around any industrial park or city business district and you`ll notice a pattern: most commercial buildings use flat or low-slope roofs. The reason is practicality. A flat commercial roof offers more usable interior space, allows for easier placement of HVAC units, and makes large-scale buildings more cost-effective to construct.

Maintenance and accessibility are other advantages. Flat roofs can be inspected and serviced without specialized equipment. This lowers ongoing maintenance costs and gives facility managers more control over building performance. When you look at the design of a flat roof commercial building, you`re really seeing decades of evolution toward efficiency and utility.

Commercial Flat Roof Types

Not all flat roofs are created equal. Different businesses have different needs, and roofing technology has evolved significantly to meet those demands. Each roofing system offers distinct advantages, from durability to energy efficiency. The most common commercial flat roof types include the following:

Built-Up Roofing (BUR)

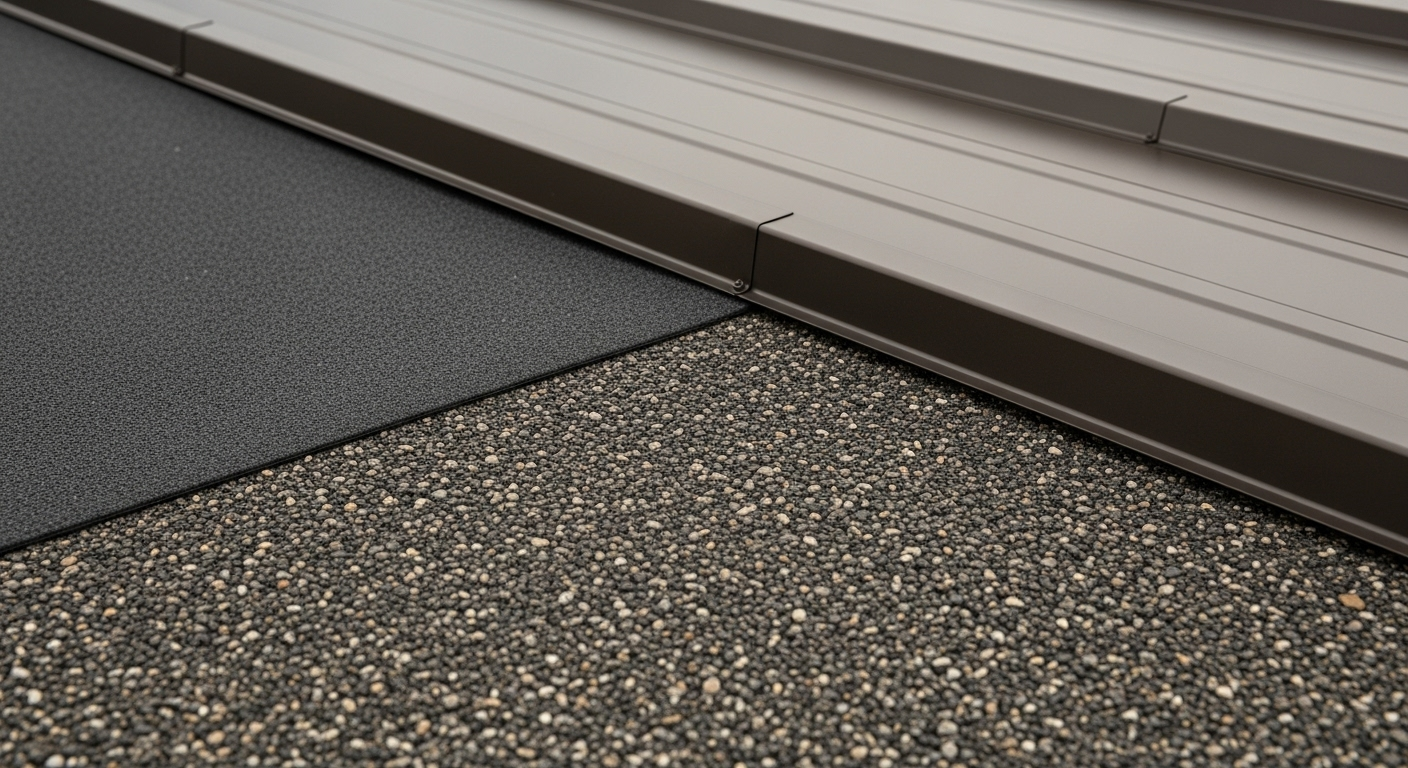

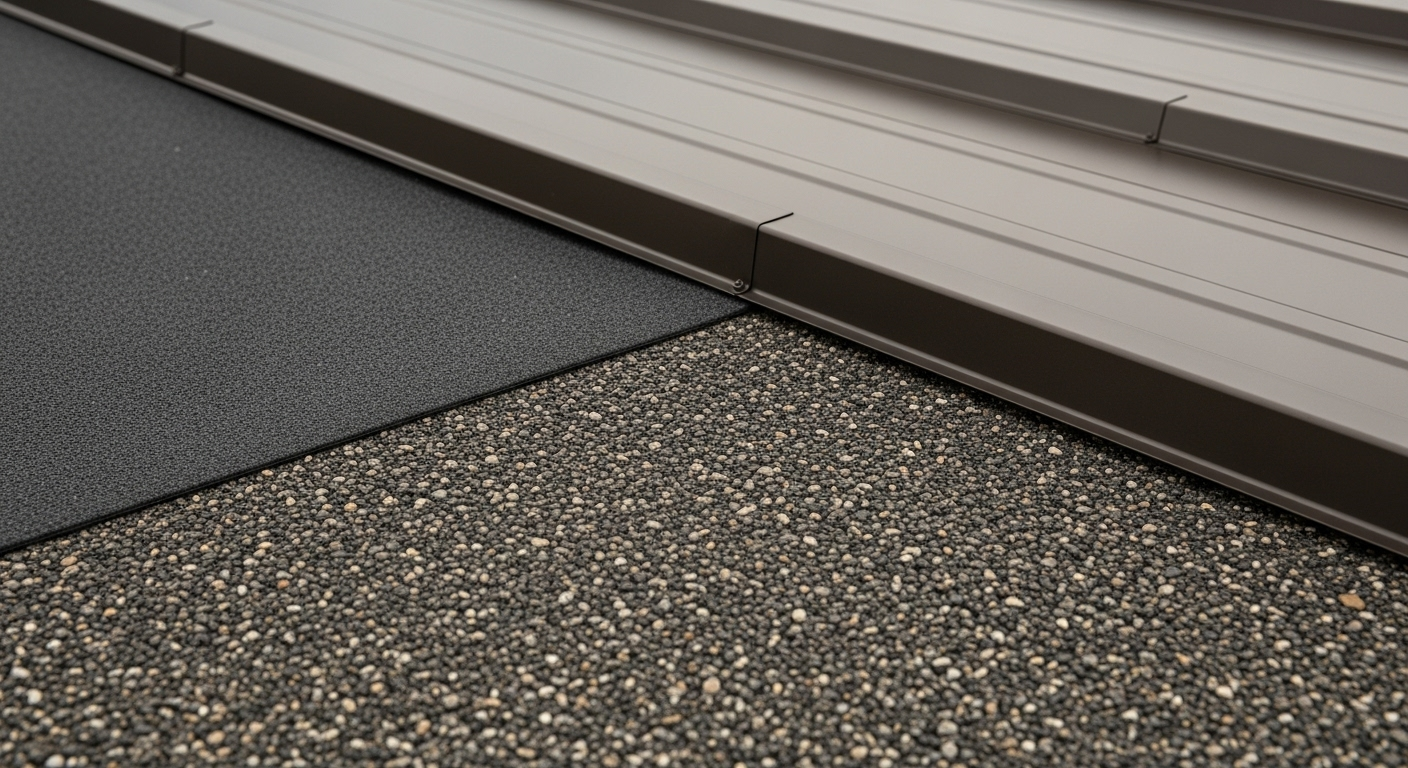

Built-Up Roofing (BUR) is the traditional flat roof system that has stood the test of time. It consists of multiple layers of asphalt, fabric, and gravel. The layers are applied over the entire roof area, creating a solid, durable surface. The top layer, typically gravel, acts as a protective barrier against UV rays and physical damage. This system is well-known for its durability and strong weather resistance, making it ideal for commercial buildings in areas with harsh weather conditions. However, the installation process can be labor-intensive and may require more maintenance compared to newer systems.

Modified Bitumen

Modified Bitumen (MB) is a more modern version of BUR that offers greater flexibility and easier installation. It combines the durability of BUR with modified asphalt that is reinforced with fiberglass or polyester. The key benefit of this system is its ability to expand and contract with temperature changes, making it highly resistant to cracking and splitting. MB roofing can also be installed using a torch-down method or self-adhesive technology. This system is perfect for businesses that want reliable protection with lower installation complexity and faster turnaround times than BUR.

EPDM (Rubber Roofing)

EPDM (Ethylene Propylene Diene Monomer) is a lightweight, cost-effective, and highly durable roofing option. It is made from synthetic rubber and is known for its excellent performance in resisting UV rays, ozone exposure, and extreme weather conditions. EPDM is particularly popular for its easy installation, as it comes in large rolls that are applied with adhesives or mechanical fasteners. This system is especially well-suited for commercial buildings that need a budget-friendly roofing option that requires minimal maintenance over the years. EPDM is commonly used in warehouses, retail spaces, and office buildings.

TPO (Thermoplastic Polyolefin)

TPO (Thermoplastic Polyolefin) is one of the most energy-efficient commercial roofing materials available. It is highly reflective, which helps to reduce heat absorption and lowers cooling costs in buildings. This roofing system is made from a blend of rubber and plastic, offering the durability of EPDM with the added benefit of heat-welded seams that make it highly waterproof. TPO is an excellent choice for businesses that want to lower their energy consumption while benefiting from long-lasting, low-maintenance protection. It`s commonly used on office buildings, retail spaces, and distribution centers looking to stay energy-efficient while protecting their assets.

PVC (Polyvinyl Chloride)

PVC (Polyvinyl Chloride) roofing is a high-performance, chemical-resistant roofing option. Known for its excellent fire resistance and ability to withstand harsh environments, PVC is ideal for commercial buildings that deal with chemical exposure, such as restaurants, factories, or warehouses. Its smooth, reflective surface also helps improve energy efficiency by reflecting solar heat away from the building. While PVC is one of the more expensive commercial flat roof options, its durability, fire resistance, and long-term performance make it an attractive investment for businesses that need a tough, reliable roof to handle tough environments.

Commercial Flat Roof Materials

When choosing a roofing system, materials matter just as much as design. Business owners should be familiar with the most common commercial flat roof materials available today.

Asphalt and Tar

Traditional, heavy-duty materials are used in built-up roofing. Reliable and time-tested, but labor-intensive to install and maintain.

Rubber Membranes (EPDM)

One of the most cost-effective options. EPDM performs well against sunlight and harsh weather, though it requires precise installation to prevent leaks.

Single-Ply Membranes (TPO, PVC)

Lightweight, reflective, and energy-efficient. Their seams are heat-welded, creating a watertight seal that improves durability and reduces cooling costs.

Sometimes used for low-slope applications, metal roofing offers excellent longevity and strength. However, it tends to be more expensive compared to other materials.

Selecting the right material isn`t only about upfront cost. It`s about performance and long-term savings. A poor choice can lead to higher maintenance, faster wear, and costly repairs down the road. That`s why experienced contractors emphasize matching commercial flat roof construction to the unique needs of each building.

Commercial Flat Roof Systems We Recommend

Contractors and roofing experts often guide business owners toward systems that balance cost, performance, and durability. Some of the most recommended commercial flat roof systems include:

- TPO Roofing Systems – Highly reflective, helping reduce cooling costs in large commercial spaces.

- PVC Roofing Systems – Excellent chemical resistance, perfect for restaurants or manufacturing plants.

- EPDM Roofing Systems – Simple, proven, and reliable, especially in climates with lots of sunlight.

- Modified Bitumen Systems – Flexible and durable, offering strong performance in colder regions.

Each system has trade-offs, but modern technology has significantly improved their lifespans. Choosing the right option requires considering the building`s function, location, and maintenance strategy. For a long-term solution, a well-installed commercial flat roof system can easily last 20-30 years with proper care.

Commercial Flat Roof Construction Process

Installing a flat roof on a commercial building is not a one-day task. It involves several steps that must be done with precision to ensure durability and performance.

Initial Inspection and Planning

Before construction begins, the contractor inspects the building structure. They check load-bearing capacity, drainage potential, and local building codes. This planning stage ensures the selected commercial flat roof construction method will work with the property.

Preparing the Substrate

The surface must be smooth, clean, and free of debris. Any old roofing material is removed. In some cases, insulation boards are laid to improve energy performance. This layer plays a big role in the final efficiency of the roof.

Installing the Chosen Roofing System

Depending on the system, the process may include rolling out EPDM sheets, heat-welding PVC or TPO membranes, or layering asphalt for built-up roofing. Each method requires specialized skills to achieve a watertight seal.

Flashing and Edge Sealing

One of the most vulnerable points in any roof is where it meets walls, vents, or HVAC systems. Contractors install flashing and sealants to keep water out of these transition areas. Skipping this step is a recipe for future leaks.

Final Inspection

Once the roof is installed, professionals check seams, flashing, and drainage. Only when the inspection passes does the project count as complete.

A well-executed installation ensures your commercial flat roof not only looks professional but also withstands decades of weather and heavy use.

Benefits of Commercial Flat Roofs

Flat roofing systems are popular for many reasons, and business owners continue to choose them for both new builds and renovations. One of the biggest advantages is cost efficiency. Flat roofs require fewer materials than pitched roofs, which makes them more budget-friendly, especially for large commercial buildings.

Maintenance is another important benefit. Contractors can easily walk on a flat surface for inspections, cleaning, or minor repairs, which keeps upkeep affordable and straightforward. Energy performance also plays a big role. Many commercial flat roof materials, such as TPO or PVC, reflect sunlight, reducing cooling costs in the summer. Adding insulation further boosts those savings.

Flat roofs also allow for smarter space utilization. HVAC units, solar panels, or even rooftop gardens can be installed on top, which is especially valuable for urban properties where space is limited. Finally, flat roofs give buildings a sleek, modern aesthetic that appeals to many companies looking for a contemporary design.

These advantages make flat roofs not only practical but also a strong long-term investment. A well-built flat roof commercial building can save money, improve comfort, and increase overall property value.

Choosing the Right Commercial Roofing Contractor

The roof is only as good as the contractor who installs it. Even the best materials will fail if they are applied incorrectly. That`s why choosing the right contractor for your commercial flat roofing project is critical.

Experience with Commercial Projects

Residential roofing knowledge doesn`t always translate to large-scale commercial jobs. A dependable contractor should have a track record of completed commercial projects and be able to discuss their approach in detail.

Knowledge of Systems and Materials

A professional roofer can clearly explain the differences between TPO, PVC, EPDM, and other commercial flat roof systems. This helps business owners select the best option for their building and budget.

Strong Warranties

Reputable contractors stand behind their work. They provide workmanship warranties that protect clients if errors show up later. These warranties are a strong sign of accountability and trust.

Proper Licensing and Insurance

Verifying licensing and insurance is essential. Proper documentation protects your business from liability and ensures that the contractor operates within industry regulations.

Clear Communication

Open communication builds trust. A reliable roofer explains costs, timelines, and possible challenges upfront, leaving no room for unpleasant surprises during the project.

Selecting a contractor isn`t just about price. It`s about long-term peace of mind. With the right partner, your commercial flat roof will deliver decades of protection, reduce energy costs, and minimize the need for frequent maintenance.

7 min read Sep 17, 2025

7 min read Sep 17, 2025 8 min read Sep 10, 2025

8 min read Sep 10, 2025 7 min read Sep 8, 2025

7 min read Sep 8, 2025